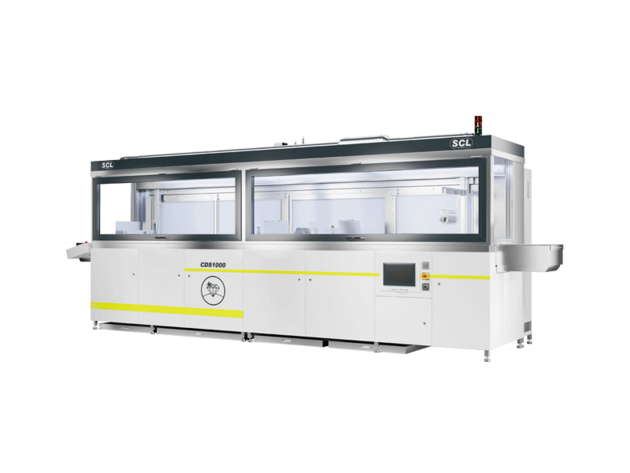

精准且安全的镜片染色工艺

CO10是一款多功能染色机,可以加工全色调和定制的渐变色镜片。机器的设计优先考虑用户的安全,采用流线型气流,防止染色混合物的蒸汽伤人。智能HMI提供了友好的界面和直观的系统,方便操作人员,可清楚地显示染色槽中正在进行的所有配方,并轻松进行渐变设置,进行无缝和高效染色。

- 多达10个可定制的染色槽。

- 2到10个模块化数字梯度系统可供选择。

- 磁旋转,用于搅拌。

- 电抛光不锈钢染色槽,轻松清洁。

- 在+/- 1°C范围内进行精确的温度调节,确保一致的染色结果。

- 水箱容易拆卸,便于维护。

- 适应性强的3通阀排水装置,适用于罐装或污水。

- 染色蒸汽的模块化通风装置,确保了工作场所的安全。

- 定制梯度大小和位置以获得所需的结果。

- 友好的界面使梯度分析和配方创建变得简单,并具有实时循环跟踪功能。