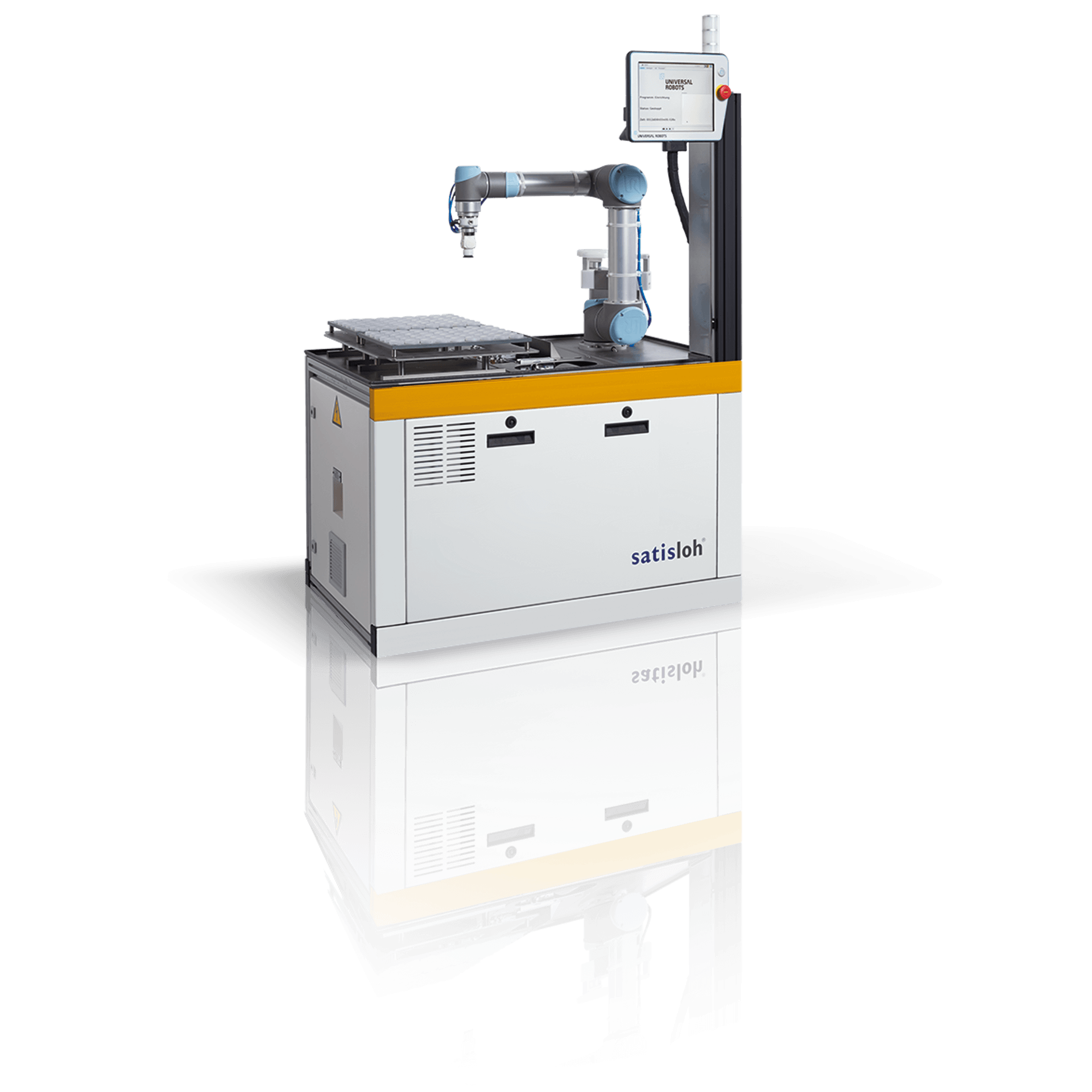

Efficient & mobile automated workpiece handling

The HS-200 is compatible with most Satisloh grinding, centering & polishing machines: SPM/SPS-200, SPM/SPS-125, SPM/SPS-50, PR-150 and C-300. Its design, an easy docking system with different suction cups and clamping options, facilitates and simplifies its use with more than one machine and different optical workpieces.

Efficient and flexible

- Handles lenses Ø 15-80 mm and up to 50 mm lens thickness.

- Compatible with most Satisloh grinding, centering, and polishing machines.

- Mobile design allows flexible use where needed.

- Modular, upgradeable design with optional washing and turning stations and double vacuum suction cup.

- Use 2 trays for highest productivity and minimized reloading – up to 408 lenses per loading cycle.

- Fully automated loading with at least 250 mm/sec increases your productivity.

Reliable

- Repeatability of +/- 0.1 mm guarantees smooth operation.

- Very high lens handling sensitivity for less damage as with manual loading.

Easy to use

- Easy docking system saves installation time.

- No changeover needed - can remain at machine during manual loading.

Tech Specs

| Capacity | 408 lenses Ø ≤ 18 mm, 2 trays per loading cycle |

| Geometries: | Spheres, aspheres, cylinders, toroids, freeforms, prisms & other optical surfaces |

| Working range: | Handles workpieces Ø 15 - 80 mm, up to 50 mm lens thickness 25 mm at the washing station |

| Dimensions (wxdxh): | 1100 x 700 mm / 43 x 28 inches |

| Weight |

All technical data are subject to change without notice. Verify details with Satisloh.

Ask us a question

Satisloh experts are ready to answer your questions. We help you make the right machine purchase decision

Request product information

Satisloh designs and manufactures machines that meet your specific requirements. Request more product information or your personalised quote today!