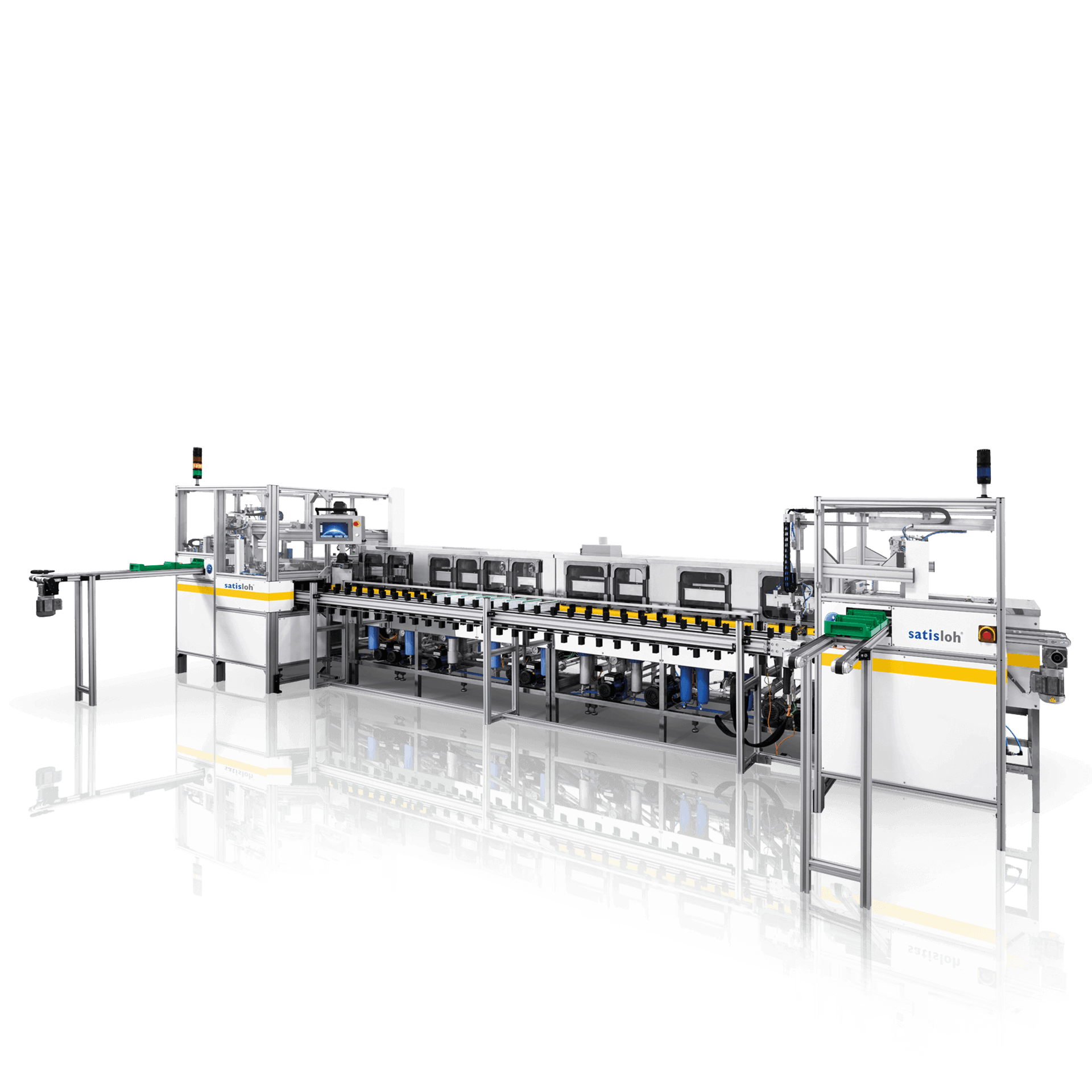

Perfectly clean lenses ready to coat

Hydra-Brush-7’s cleaning and high pressure rinsing cycles remove residues of polish, ink, tape or glue particles, and finger prints, while the air blades effectively dry the lenses making them ready for inspection.

Reliable and efficient

- In-line process fits seamlessly with automated lens production flow, reducing production disruption

- High throughput, Hydra-Brush-7 is able to process up to 500 lenses per hour

- 7 chambers

Flexible for production needs

- Compatible with both alloy-free and traditional alloy lens production

- Full compatibility with MES-360, Satisloh’s manufacturing execution system

Environmentally friendly

- Low tap water consumption due to cascading from clean to dirty tanks

Easy to use and maintain

- The patented conveyor housing protects the driver chain from water and detergent, meaning less maintenance and downtime, no cross contamination between chambers, and reduced detergent consumption

- Easy access to key components for simplified maintenance

- User-friendly HMI and touch screen

Tech Specs

| Productivity: | Up-to 500 lenses/hour |

| Lens materials: | all organic and mineral glass lenses |

| Dimensions (wxdxh): | 7020 x 1520 x 1370 mm/ 276 x 60 x 54 inches |

| Weight: | 1750 kg/ 3858 lbs |

All technical data subject to change without notice. Verify details with Satisloh.

Documents

Ask us a question

Satisloh experts are ready to answer your questions. We help you make the right machine purchase decision

Request product information

Satisloh designs and manufactures machines that meet your specific requirements. Request more product information or your personalized quote today!