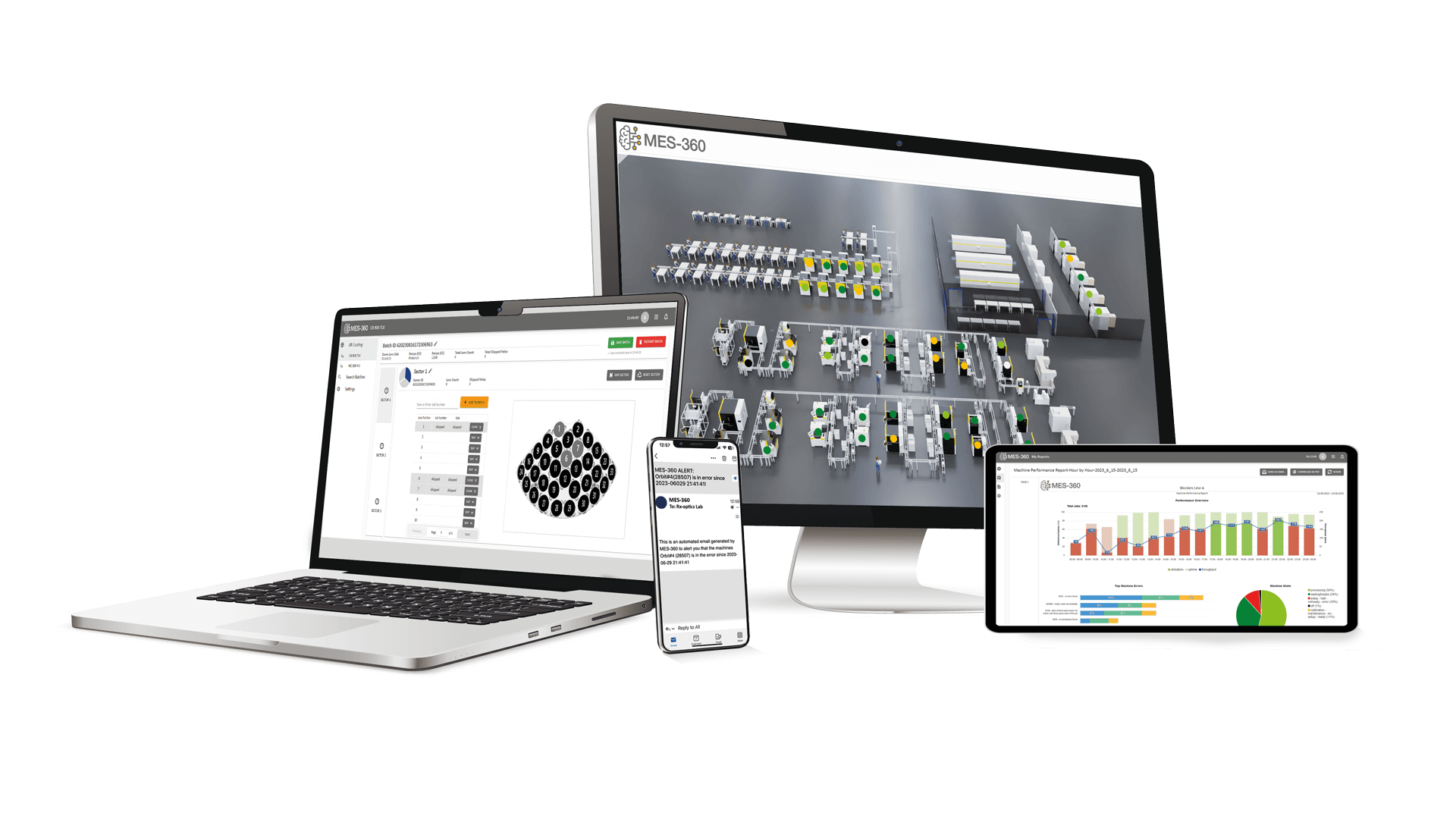

Improve your Lab performance, equipment utilization & quickly resolve issues in real-time

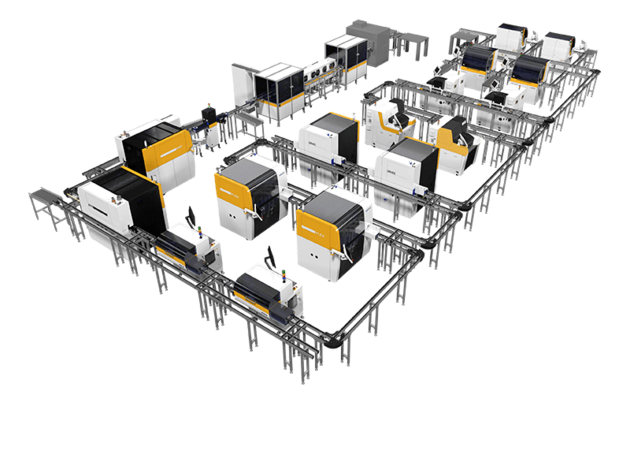

MES-360 can help improve overall equipment effectiveness (OEE) & total cost of ownership (TCO) in your lens manufacturing process.

Proactively manage your production and job breakage with the software´s real time data. MES-360 maximizes production throughput and cost-saving.

Three modules to fit any optical lab manufacturing needs

- MES-360 MM - Machine Monitoring

- MES-360 CR - Conveyor Routing (with Intergrated Smart Conveyor only)

- MES-360 ETK - E-Ticket Manager (with E-Ticket System only)

Functionalities

in MES-360

- Real-time Production Monitoring of the lens manufacturing process, including machine status, productivity, & quality control parameters. This allows labs to detect and correct errors before they become major issues, improving product quality, consistency and yield.

- Data Platform for data collection and advanced analytics tools, allowing users to evaluate production data & identify trends or patterns that contribute to issues in the production process. This helps labs optimize their production processes and improve overall efficiency.

- Quality Management with a wide range of quality control tools to ensure each lens meets the required specifications. Includes inspection & testing tools, allows for lens measurement during different production steps and works with automated inspection machines.

- Machine Integration links production machine (Satisloh & 3rd party) and hardware for seamless data transfer and integration with other workflows. This provides greater flexibility and scalability in the production process.

- Customizable Workflows to meet the specific needs of the lab production environment. Includes setting up rules for job routing, tracking, & job priority handling with Satisloh´s Integrated Smart Conveyor.

Highlights

Production Efficiency

Monitor your lens production processes in real-time to quickly and effectively identify and correct issues, increasing efficiency and enabling traceability.

Equipment Maintenance

Track & schedule preventive maintenance tasks. This helps prevent breakdowns and extends the equipment's lifespan, improving overall OEE.

Quality Control

Detect & correct issues before they leave your production site. Reduce the number of defective products, ensuring high-quality output.

Waste Reduction

Analyze production data & identify areas of improvement. By identifying & addressing areas of waste, labs can reduce their environmental impact.

Machine Performance

Get reports on machine down, setup times, & other factors that impact your OEE. Make targeted improvements to your production process.

Automation Transition

Conveyor control helps labs transition to full automation workflows, increasing productivity, preventing job mishandling & improving efficiency.

Video

Tech Specs

| Server requirements | Physical or virtual server Min. 2.5 GHz, 8 core CPU Min. 16 GB RAM Min. 500 GB free space on hard drive Min. 1 Gbit network Windows server 2012 32/64 bit Cloud server available |

| Client requirements | PC, ThinClient, TabletPC with WIN OS Min. 2 GHz dual-core CPU Min. 4 GB RAM MS WIN 7/8/10 32/64 bit |

All technical data are subject to change without notice. Verify details with Satisloh

Release Notes

Ask us a question

Satisloh experts are ready to answer your questions. We help you make the right machine purchase decision

Request product information

Satisloh designs and manufactures machines that meet your specific requirements. Request more product information or your personalized quote today!